Using electrochemistry, University of Oregon researchers have developed a way to make iron metal for steel production without burning fossil fuels.

The series of chemical reactions turns saltwater and iron oxide — cheap and abundant ingredients — into pure iron metal.

If scaled up, the process could help decarbonize one of the largest and most emissions-intensive industries worldwide. It might someday replace the carbon-spewing industrial blast furnaces currently used to produce the iron that feeds steel manufacturing.

The researchers report their findings in a paper published Feb. 5 in the journal Joule.

In 2022, almost 2 billion metric tons of steel were produced worldwide, destined for cars, buildings, infrastructure and hundreds of other uses. Converting the iron ores found in naturally occurring minerals into pure iron is currently one of the most fossil fuel-intensive parts of the steel manufacturing process.

Decarbonizing this step would do roughly as much to reduce greenhouse gas emissions as converting every gas-guzzling vehicle on the roads to electric, said Paul Kempler, a research assistant professor at the UO and director of the Electrochemistry Masters Internship Program.

But developing a green chemical process that’s cost-competitive with traditional methods is challenging, Kempler said. Anything that requires expensive ingredients to make the chemistry work, or generates byproducts that are difficult to dispose of or use, won’t be economically viable on an industrial scale.

“The reason we got excited about this chemistry is that our reactants are two things that are very cheap: saltwater and iron oxide,” he said.

Kempler’s team created a setup where electricity drives complementary chemical reactions. On one side of the reactor, iron oxide gets turned into iron and sodium hydroxide. On the other side, sodium chloride — table salt — gets turned into chlorine. The two sides are separated by a semipermeable membrane that allows positively charged ions to flow through, balancing out the chemical reactions so they can keep running.

Importantly, the byproducts of the chemical reaction can all be repurposed. The sodium hydroxide that’s generated can go back into the reactor or be collected and used in carbon-capture technology. And chlorine is valuable in other industrial processes.

Kempler’s lab isn’t the only group trying to use electrochemistry to solve the iron production problem. Its approach stands out in a few ways: It works at the temperature of water used to steep green tea, rather than under extreme heat. And the sodium hydroxide it generates can be fed back into the reactor, so that key ingredient doesn’t need to be continually added.

The sodium hydroxide can also help purify incoming iron ores, preventing glitches to the chemical process caused by certain impurities in the starting materials, said study lead author Berkley Noble. Noble worked on the process as a student in the Electrochemistry Masters Internship Program and is now working for a company developing electrochemical ways to make magnesium.

“That’s the beauty of this process,” he said. “Using one of the co-products of the cell, you can purify the incoming feed.”

The basic design is based on a well-established electrochemical reaction called the chlor-alkali process, which has been used since the 1800s to produce two widely used industrial chemicals. Because that reaction has already been optimized and time-tested on a large scale, Kempler’s lab used it as a jumping off point to design a new approach to ironmaking that would be practical and cost-effective to scale up from the lab to industry.

“As soon as we started talking to people who make steel, we saw the amount of material they work with is very different than the amount that electrochemists work with,” Kempler said. “We had to make some much bigger reactors than we’re used to.”

Right now, their reactor has roughly the footprint of a sheet of paper and draws power from a standard wall electrical outlet. That’s big for a research lab, but it is still small by industrial standards.

The lab has filed a patent for its process, and the team is collaborating with the National Energy Technology Laboratory to confirm that the iron generated from the reactions can indeed be used in steel.

The lab also is building prototype devices and working with partners in industry to explore scaling up the approach. The ultimate vision is a plant with stacks of electrochemical cells, all cranking out iron.

Using calculations based on the cost of running the chlor-alkali process, “our model shows us that if we can build a plant at similar size and cost, we could make iron at prices competitive to (using) fossil fuels but without the emissions,” Kempler said.

Kempler recently received more than $730,000 in new funding from the U.S. Department of Energy to further advance the green process. In collaboration with Erica Fischer at Oregon State University and the electrochemical company De Nora, his team hopes to improve the electrodes and make the electrochemical process work with lower-quality iron ores that are abundant and easy to source.

—By Laurel Hamers, University Communications

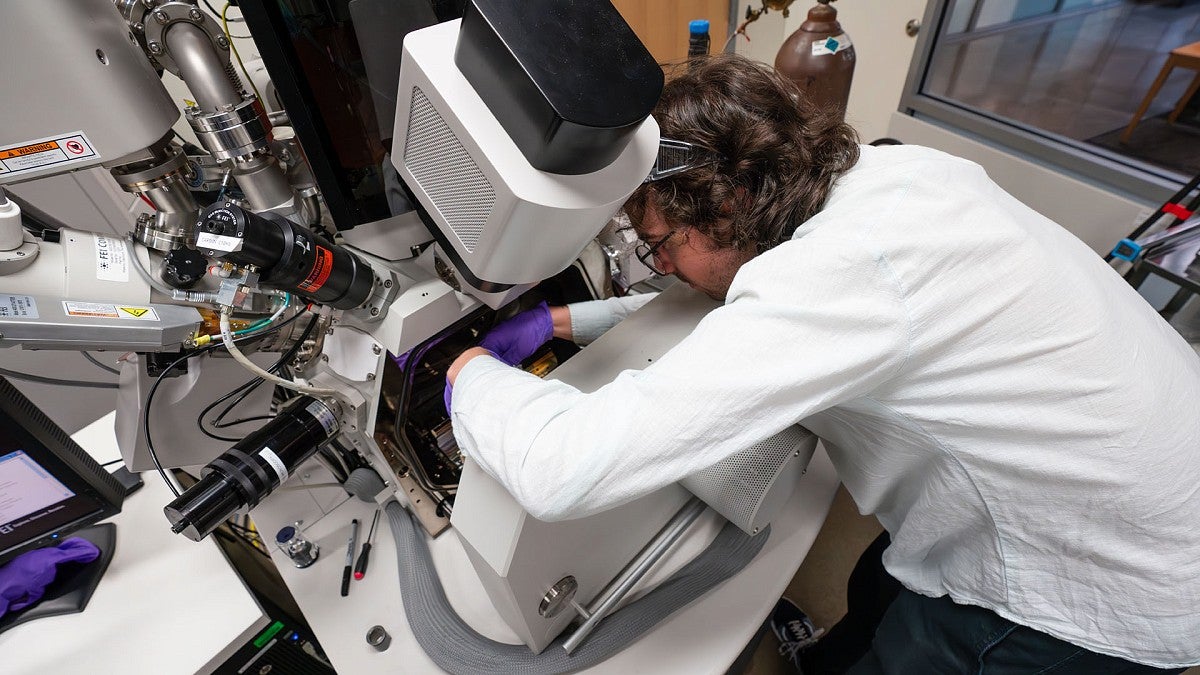

—Top photo: Researcher Louka Moutarlier at work in the Paul Kempler lab

This research was funded by the U.S. Department of Energy. The team also received support from a University of Oregon Translational Research Grant and the Oregon Center for Electrochemistry.

Editor's note: This story was updated March 6, 2024, to include recently awarded grant funding.