Glowing Implants, Created Serendipitously

Bioengineers and chemists design fluorescent 3D-printed structures with potential medical applications

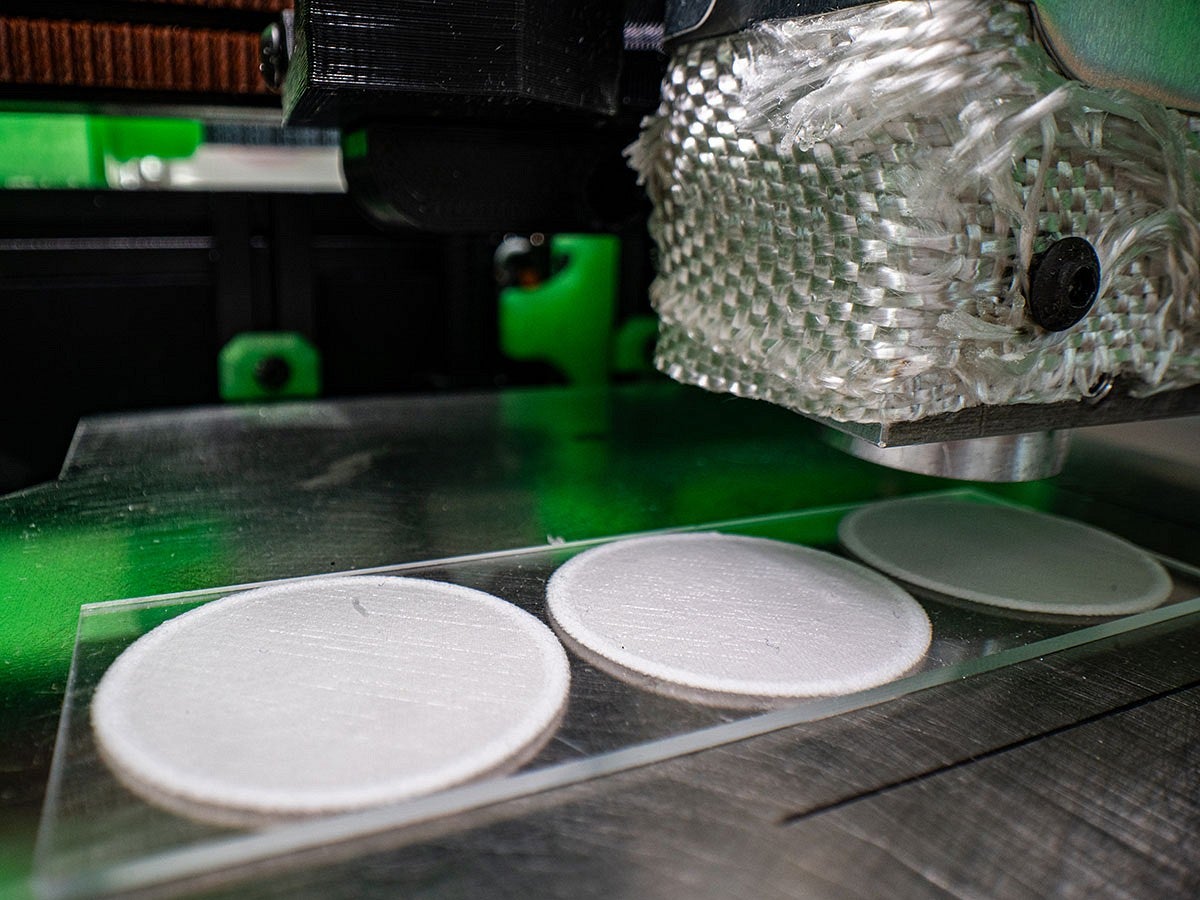

In a process as simple as stirring eggs and flour into pancakes, University of Oregon researchers have mixed fluorescent ring-shaped molecules into a novel 3D printing process. The result: intricate glowing structures that support the development of new kinds of biomedical implants.

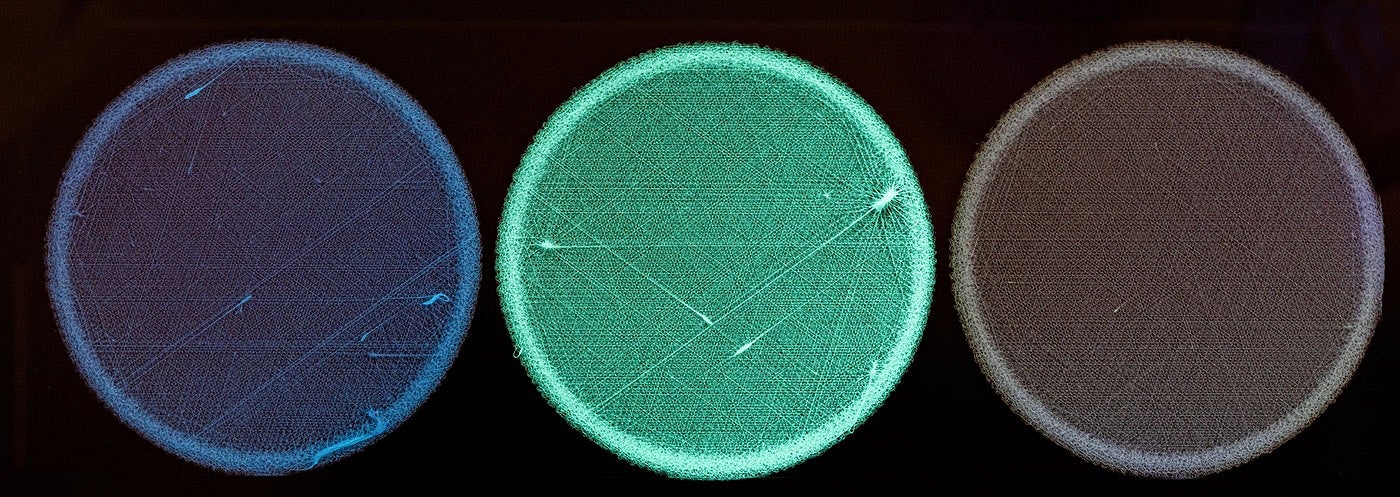

The advance solves a longstanding design challenge by making the structures easier to track and monitor over time inside the body, allowing researchers to easily distinguish what’s part of an implant and what’s cells or tissue.

The discovery emerged from a collaboration between Paul Dalton’s engineering lab in the Phil and Penny Knight Campus for Accelerating Scientific Impact and Ramesh Jasti’s lab in the chemistry and biochemistry department in the UO’s College of Arts and Sciences. The researchers describe their findings in a paper published this summer in the journal Small.

“I think it was one of those strange times when we said, ‘Let’s try it,’ and it pretty much worked immediately,” Dalton said.

But behind that simple origin story are years of specialized research and expertise in two very different fields before they finally came together.

Both labs might have stayed in their own lanes if not for a casual conversation when Dalton was a new professor at the UO, eager to make connections and meet other faculty members. He and Jasti tossed around the idea of incorporating the nanohoops into the 3D scaffolds that Dalton already was working on. That would make the structures glow, a useful feature that would make it easier to track their fate in the body and distinguish the structures from their surrounding environment.

“We thought it probably won’t work,” said Jasti, who also directs the Materials Science Institute. But it did, quite quickly.

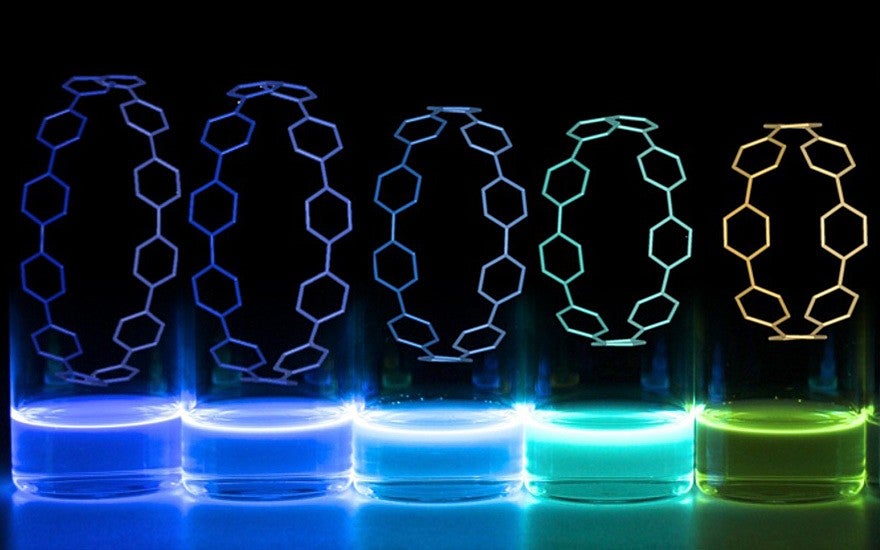

People had tried to make the scaffolds glow in the past with little success, Dalton said. Most fluorescent molecules break down under the lengthy exposure to heat required for his 3D printing technique. The Jasti lab’s nanohoops are much more stable under high temperatures.

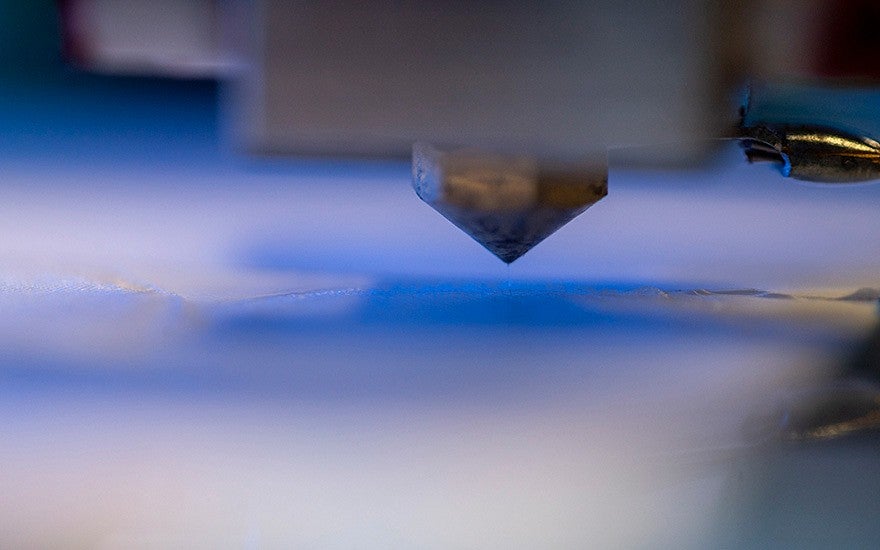

Though both groups might make their craft look easy, “making nanohoops is really hard, and melt electrowriting is really hard to do, so the fact that we were able to merge these two really complex and different fields into something that’s really simple is incredible,” said Harrison Reid, a graduate student in Jasti’s lab.

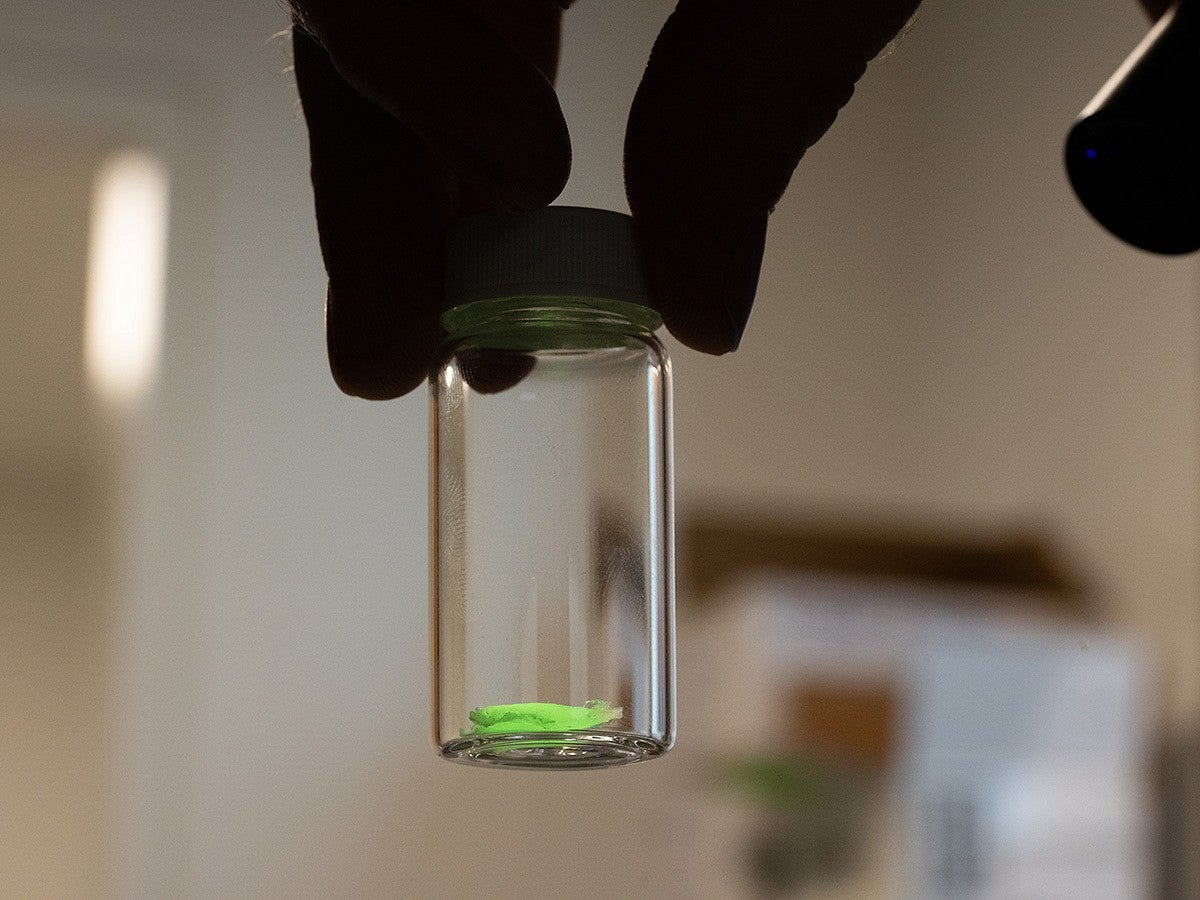

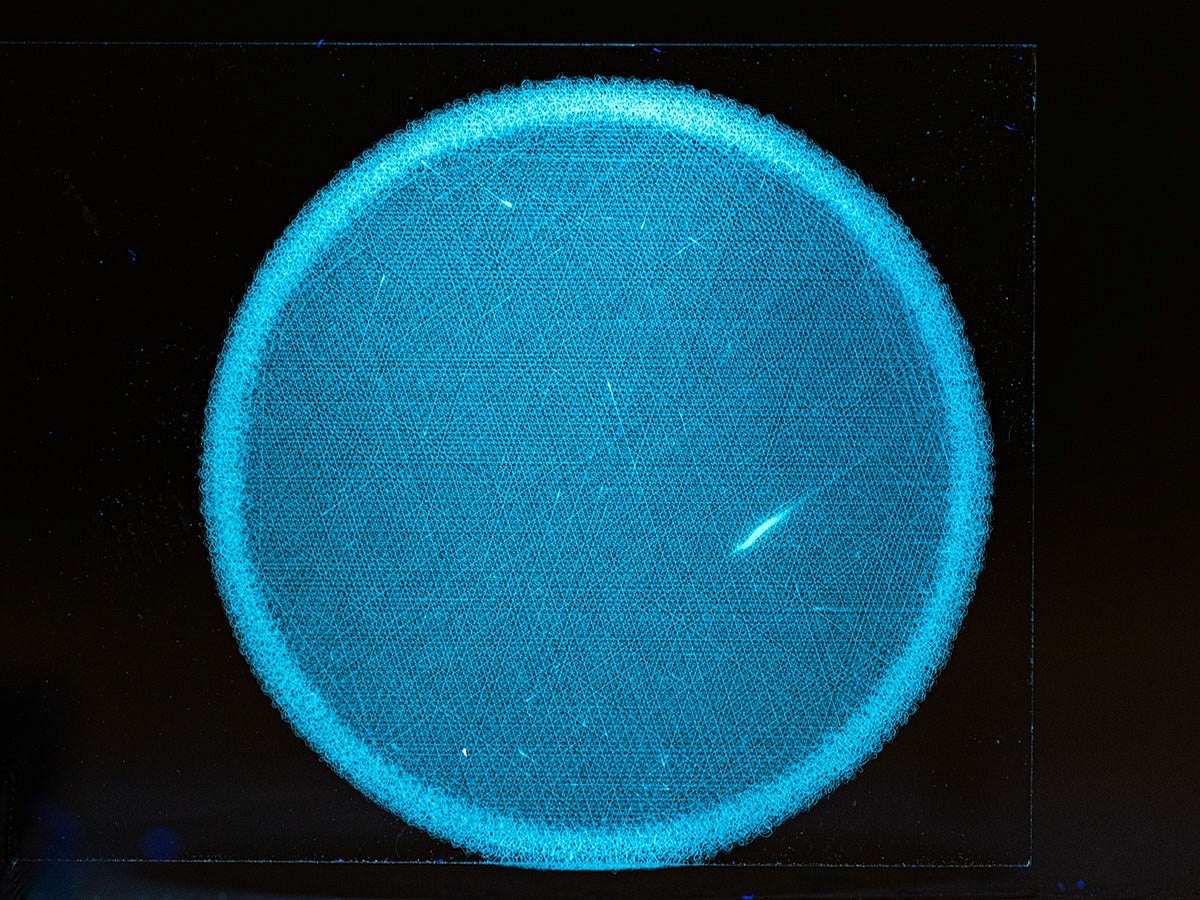

Just a small amount of fluorescent nanohoops mixed in to the 3D printing material mixture yields long-lasting glowing structures, the researchers found. Because the fluorescence is activated by UV light, the scaffolds still look clear under normal conditions.

The nanohoops glow under UV light.

Because the fluorescence is only activated by UV light, the resulting scaffolds don’t glow under ambient lighting.

While the initial concept worked very quickly, it’s taken several years of further testing to fully scope out the material and assess its potential, said Patrick Hall, a graduate student in Dalton’s lab.

For instance, Hall and Dalton ran a battery of tests to confirm that adding the nanohoops didn’t affect the strength or stability of the 3D-printed material. They also confirmed that adding the fluorescent molecules didn’t make the resulting material toxic to cells, which is important for biomedical applications and a key baseline that needs to be met before it can move closer to human application.

The researchers—Ramesh Jasti, Paul Dalton, Patrick Hall and Harrison Reid—shine a UV light onto one of the scaffolds made with nanohoops.

A close-up of a scaffold made with nanohoops, glowing blue under UV light.

The team envisions a range of possible applications for the glowing materials they’ve created. Dalton is particularly interested in the biomedical potential, but a customizable material that glows under UV light might also have use in security applications, Jasti said.

They’ve filed a patent application for the advance and eventually hope to commercialize it. And both Jasti and Dalton are grateful for the serendipity that brought them together.

“We get cool new directions by having people who don’t usually discuss their science come together,” Dalton said.